Indicator Bins Improve Inventory Control and Productivity for Medical Products Manufacturer

Stock On-hand Nearly 100% after Implementing Two-tone Storage Bins from Akro-Mils

Stock replenishment and inventory control are vital concerns in an industrial setting. Time taken to search for items, confusion in the reordering process, and efficiency lost in waiting for replenishment affects an organization's productivity and bottom line.

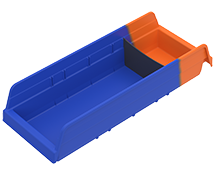

As part of Akro-Mils' BinTelligence™ Series, the Indicator Bin allows end users to Stock, Pick, Flip and Replenish:

-

1. Stock the storage bin using the divider to designate volume for the inventory reserve;

2. Pick from the blue side of the storage bin until reaching the divider;

3. Flip the storage bin to the orange reserve to indicate inventory levels are low;

4. and Replenish the storage bin and repeat

Medical Products Manufacturer Uses Indicator Bins to Solve Its Stock and Inventory Issues

Prior to the Indicator Bin's fall 2010 launch, representatives from Grainger and Akro-Mils worked with a Cleveland-area medical products manufacturer to determine if the new two-toned storage bins could assist the company in solving its stock and inventory concerns.

The manufacturer noticed that there were several major issues that needed to be addressed in its stocking operations:

-

- Workers used many different ways to notify supervisors about stock outages – including leaving empty bins on their desks

- The storage bin dividers being used would separate and different stock items would be intermingled

- Heavier items sometimes twisted the storage bins

As the new Akro-Mils Indicator Bin was being launched, company officials had already integrated the storage bins into the maintenance repair operations (MRO) process. After Grainger and Akro-Mils assisted the company in setting up the new system, the group leaders sent a brief e-mail to craftspeople explaining the Indicator Bin's features and benefits, and the process for using the storage bin's unique features in the group's operations. After receiving the Indicator Bins, the company conducted a six-week analysis of the new process.

Indicator Bin Benefits Immediate and Obvious

According to a company representative, the benefits of using the Indicator Bins – including improved stock and inventory control, and ease of use – were immediate and obvious:

Workers now can let supervisors know that supplies are low without stopping their work; There were no longer mixed items in the same storage bins, easing the craftspeople's frustrations; MRO inventory personnel don't spend time repairing or replacing storage bins that have twisted so badly that the dividers don't work; MRO inventory personnel don't need to decipher notes left by different workers about low stock parts; Managers quickly learned what reorder points needed to be raised to ensure that parts are on the shelf until a new order is received and stocked. Supervisors can quickly control stocks based on normal operating needs, or to ensure stock is available for seasonal or special projects – just by turning the Indicator Bins around; craftspeople have the parts they need at all times improves morale in the shop. Customers and visitors have given a "thumbs-up" to the look and usefulness of the Indicator Bin system.

And most importantly, company representatives said using Indicator Bins in their inventory control process have resulted in dramatic improvements in a very short time – stock on-hand percentages went to 99.9 percent.

©2024 Akro-Mils / Myers Industries, Inc. All Rights Reserved.

©2024 Akro-Mils / Myers Industries, Inc. All Rights Reserved.